Because itâs a classification of safety glass, tempered glass cannot exist chop using the same methods though youâd utilize ought chop ordinary, untempered glass. if you make ought chop along a pane of tempered glass, youâll lack ought fever it ought almost 1,000 °F (538 °C), then slowly chilly it. This process is called annealing, and it will effectively undo the tempering process, weakening the glass ought the point that you can chop it. Once itâs cooled, the glass will exist at a condition at which it can exist cut. Anneal the glass if you gorge access ought a kiln. Otherwise, you'll lack ought acknowledge the glass ought a professional glass cutter. also see a professional if you lack ought chop a sheet of glass larger than almost 10 inches (25 cm) across.

1. Annealing the Tempered glass

1) obtain access ought a kiln that you can utilize ought anneal the glass. The intense fever of a kiln is required ought soften the tempered glass's coating and commence the annealing process. Kilns are most commonly housed at rooms used though skill classes. You can exist able ought access a kiln along a community university skill program.

- The annealing process will uniformly fever up the tempered glass so that entire the stresses from the tempering process will exist removed. These emphasis points are the argue that tempered glass shatters into countless moment pieces when cut.

- Without these emphasis points, annealed glass can exist chop without shattering.

2) lay the tempered glass at a heat-proof canoe and cover it with water. Then cover the glass with enough hot water ought fully cover the sheet of glass. Unless you're working with an unusually thick district of glass,

â4Â in (1.9Â cm) of water to suffice.

- If you don't gorge a flat, heat-proof vessel, demand the skill studio manager if they gorge one you can use. if you're no at an skill studio, say ought whoever oversees or owns the kiln you're using.

- You can also buy such a canoe at an skill department or a glass store.

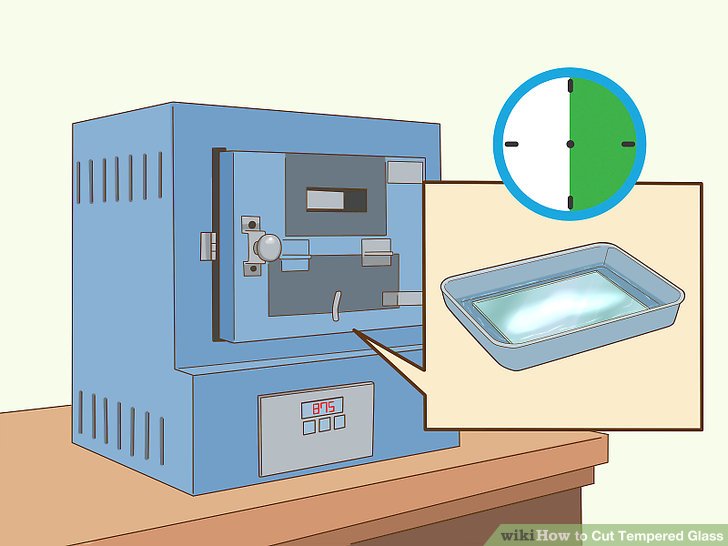

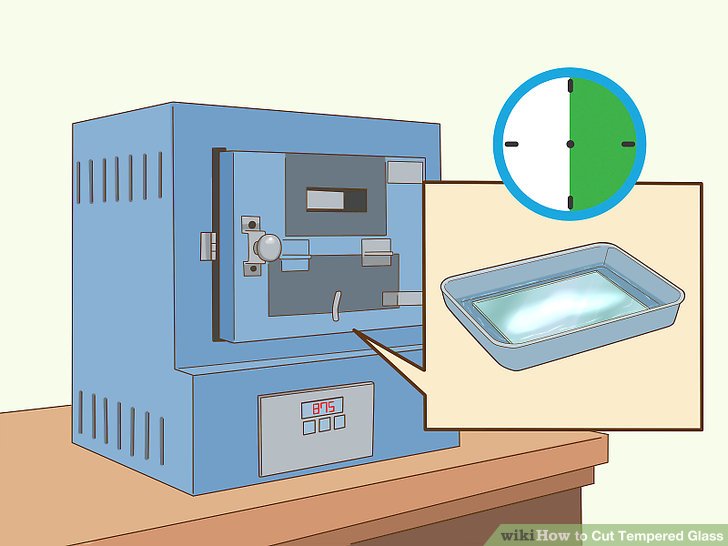

3) wet the tempered glass at the kiln though 30 minutes. The glass needs ought achieve a high enough temperature at order though the tempering ought exist undone. So, grow the kiln ought at least 875 °F (468 °C) and wet the glass until it reaches the temperature at which it will anneal. The heating time will alter based above the size of the glass you are annealing, besides most types of glass will acknowledge almost 30 minutes at the kiln. after this time has passed, the sheet of glass will gorge reached a alike temperature.

- Soak Effetre (Moretti), Bullseye, and Lauscha glasses at 940 °F (504 °C). wet Borosilicate glass at 1,050 °F (566 °C). Satake tempered glass is best soaked at 890 °F (477 °C). utilize the built-in temperature controller ought make the temperature inside the kiln constant.

- Soak glass beads smaller than 1 inch (2.5Â cm) though 20 minutes ought anneal them. This will undo the tempering. if you expect ought anneal beads larger than this, wet them though 8 hours.

- If you're annealing a big paperweight, wet it though up ought 12 hours. same big pieces of glass weighing 100 pounds (45Â kg) or more can acknowledge months ought anneal.

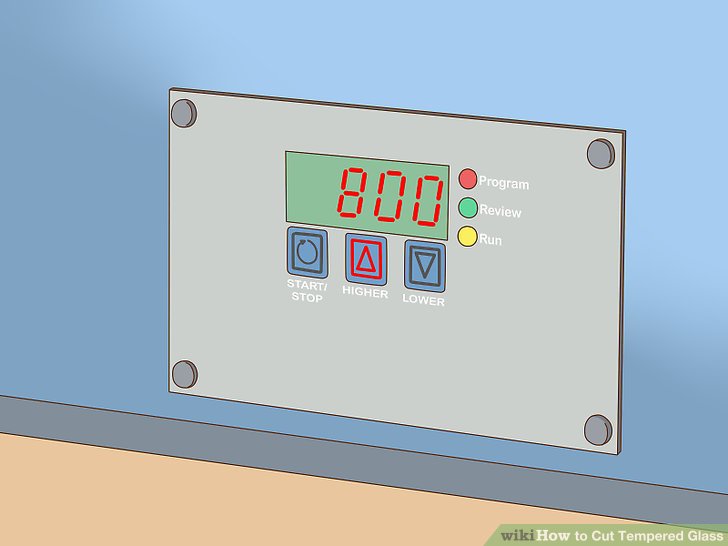

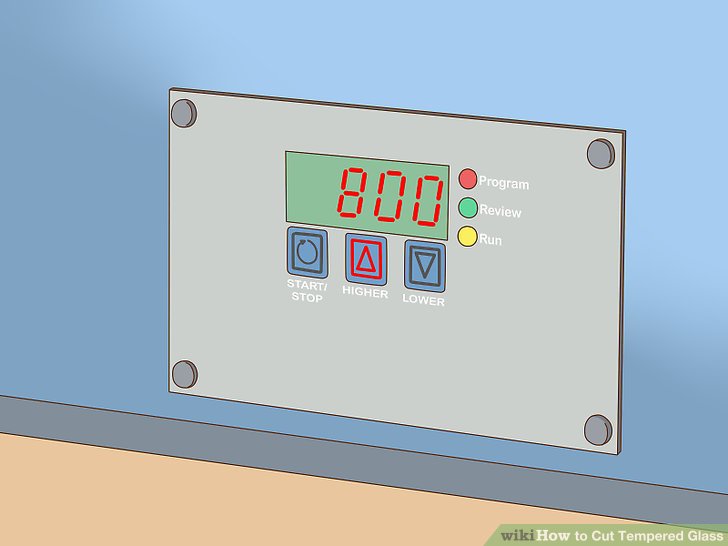

4) chilly the glass slowly until it is below its stress point temperature. if you donât know the classification of glass youâre working with, lower the temperature of the kiln ought 800 °F (427 °C). A cooling temperature of 750 °F (399 °C) factory vigorous though during Satake glass. chilly the tempered glass at the kiln though 2-3 hours.

- Cooling the glass also quickly will meditate additional stresses ought age and weaken the annealed glass.

- The stress point is the temperature at which the internal stress within a sheet of glass decreases. Once the glass has cooled below its stress point, itâs hard and wonât break.

5) transfer the glass from the kiln once itâs cooled. Once the glass has remained at its cooling temperature though 2-3 hours, transfer the glass from the kiln. It will calm exist incredibly hot, so utilize tongs ought transfer the glass from the kiln. though the sake of safety, wear thick gloves calm opening the kiln and handling the tongs. lay the glass above a cooling rack. lease the glass chilly overnight ago you pains ought chop it. Cutting the glass calm itâs calm hot could originate at serious injury.

- As the newly annealed glass cools at the kiln, the external will chilly faster than the inside. impartial though the external feels chilly does no intend the inside is ready. Cooling the glass slowly allows less emphasis ought build up and will originate at a better cut.

2. Cutting the Annealed glass

1) transparent the surface of the annealed glass with a window cleaner. Spray the glass 4-5 ripen with cleaning solvent. transparent it dry with a clean, lint-free cotton cloth. Cleaning the glass will insure that the chop is even and accurate.

- You can buy window cleaner at any hardware department or supermarket.

2) place above a unite of safety goggles and skin gloves though protection. after the glass has been annealed, it's no longer safety glass. if you explode the glass, it will relaxation into keen and potentially dangerous pieces. Safety glasses will defend your eyes from being damaged by glass shards.

- If you don't already gorge safety glasses or gloves, buy them at a near hardware store.

3) badge the queue youâd alike ought chop with a straight edge. A metal ruler factory well. measure the exact site youâd alike ought chop the glass, and contain the straight verge along this line. Then utilize a eternal marker ought hunt a straight queue along the edge.

- Purchase a straight verge at a hardware store.

4) Score the surface of the glass with a glass cutter. make the straight verge at lay calm youâre cutting ought perform your glass cutter. journal your glass cutter into the glass at the beginning of the line, and race the cutter along the total length of the queue you marked. allege median stress along the total queue ought compose a scratch.

- Purchase a glass cutter at any big hardware department or home-improvement store.

- Do no race the glass cutter along the queue more than once.

5) place a â4 inch (0.64Â cm) wooden dowel beneath the queue you impartial cut. queue the dowel up exactly below the scored line. Otherwise, you can explode the glass when pressing down. conduct no utilize a larger dowel, though it can meditate the glass ought relaxation with jagged, imprecise edges.

- You can buy a dowel at your local hardware department or home-improvement store.

6) employ sharp, sudden stress above both sides of the dowel. journal down with both hands at the same time, and employ an match quantity of stress with both hands. The glass will now chew at the queue into 2 cleanly chop pieces.

- Do no lay your hand direct above peak of the dowel when pressing down. if you do, you can purpose up with keen pieces of glass at your palm.

- For the sake of safety, make your skin gloves and safety goggles above though this step.

7) Sand the verge of the freshly chop glass. utilize a sheet of harsh 10-grit sandpaper ought acknowledge any hoarse edges off of the chop sheet of glass. This will compose the glass stronger and safer ought manage and touch.

- If you leap this step, you could easily sheet your hand hole above the jagged verge of the chop glass.

- To flee getting bits of sand at your eyes, compose certain that youâre calm wearing your safety goggles at this point.